Grade Control for Excavators

Maximum efficiency for your excavator. Everyone talks about it, but only Trimble delivers.

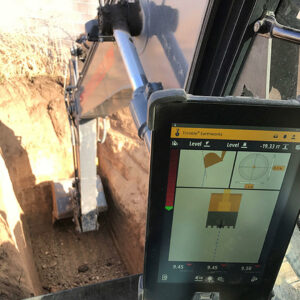

New! Augmented Reality for Excavators

Operators can now view 3D models in a real-world environment at a true-life scale, in the context of existing surroundings. On the Trimble Earthworks Grade Control Platform display, the model is overlaid onto existing ground giving the operator a better understanding of the work that needs to be done. Visibility of the bucket gives operators better situational awareness to be able to keep surrounding people and objects safer. Users can easily understand 3D models, cut/fill information, slope data and other bench points and reference points in context, without the need to interpret complex 2D plans or stakes.

Configuration Options for Excavators

| Product | Applications | Configurations | Description |

|---|---|---|---|

| 3D |

|

Single GNSS | Measures the position of the bucket and compares that to design data for rough grading and mass excavation on complex design surfaces |

| Dual GNSS | Measures the exact position and heading of the bucket for rough grading and mass excavation on steep slopes and complex design surfaces | ||

| Universal Total Station (UTS) | Total station based system for extreme accuracy for lift and layer control, material monitoring, or where GNSS is not the ideal solution because of overhead obstructions | ||

| 2D |

|

Depth, Slope and Elevation Control | Highly flexible system for excavation, trenching, grading and profile work |

| Depth and Slope with Bench Reference | Simply enter the desired depth and slope, or bench using your bucket. The system will provide guidance to a depth or slope based on distance from a known point or “bench” on the ground. | ||

| Laser Reference | A rotating grade laser provides a reference plane across the job site. | ||

| Laser Reference with Heading | The excavator can be rotated without the need to re-enter the desired depth and slope to maintain consistent accuracy. | ||

| Depth and Slope with GNSS | Keep the easy to use Depth and Slope, or, Bench and Go workflows, and leverage GNSS to move around the site without having to use touch points or laser reference to carry your elevation. In addition you can also rotate and maintain constant slopes as the GNSS also provides heading. |

3D Grade Control for Excavators

Trimble 3D grade control can be installed on excavators with standard buckets or tilt buckets. Tilt rotator attachments are also supported.

Work in Any Environment

- Use either GNSS or total stations

- Measure the precise 3D position of the teeth of the bucket

- A simple 2D GNSS Bench and Go workflow means no office software and no 3D models required

- Work up to 20 meters underwater with a deep underwater kit

- Quickly perform complex tasks and simplify finishing slopes with accurate 3D positioning

- Shape V-ditches and operations where the excavator is digging a slope that is not perpendicular to the boom

Excavator Automatics

With Trimble Earthworks, you can now take advantage of the first integrated 3D aftermarket grade control automatics for excavators and tilt-rotator attachments. Excavators can work semi-automatically, allowing operators to create smooth, flat or sloped surfaces more easily. Achieve grade consistently, with high accuracy and in less time by automating excavator operation with Trimble Earthworks.

2D Grade Control for Excavators

Trimble’s 2D grade control system for excavators is ideal for earthmoving contractors looking to improve their excavation productivity and profitability.

- Get into grade control at a very affordable price

- Uses an angle sensor, dual axis sensor and laser catcher to measure the relationship between the body, boom, stick and bucket

- Guides the operator to the desired depth and slope and determines where the bucket teeth are and should be

- Upgrade to a 3D grade control system as your business grows